Polyurea is a truly remarkable material. With proper surface preparation and priming (where required), it can be sprayed onto almost any substrate, to which it will stick with unparalleled tenacity. It is used (in conjunction with other ballistic materials) to stop bullets and shrapnel as a protective layer on military Humvees, and was used to coat the walls and ceiling of the U.S. Pentagon for protection against bomb blasts. Yet, it is flexible enough to bridge cracks in shifting substrate, like concrete, and attractive enough to be used as a decorative protective coating on oceangoing ship hulls.

Many formulations of polyurea are available from many manufacturers. While all are durable coatings, some are formulated to be more colorfast in UV light exposure. Other formulations are tuned to be harder and less flexible to support greater loads. Still others have elements that make them very good for chemical resistance or exposure in food processing environments. We work closely with the customer and the manufacturers to identify the best polyurea system for your application, and to ensure that it is installed correctly.

Unlike many other coatings such as polyurethanes, polyurea and its hybrids are not sensitive to environmental temperature or humidity while they are being applied. This allows a much broader window of conditions and times for application, and mitigates concerns about coating integrity or moisture absorption that can compromise a coating job.

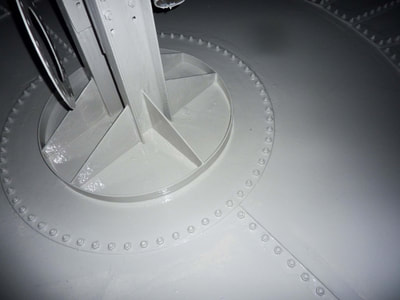

Titan Industrial Coatings operates multiple mobile High Pressure Plural Component (HPPC) polyurea rigs that can be brought to your site for application. We even have small portable units that can be brought inside of your facility through a standard man door to gain access when proximity to a trailer is not possible. Our highly specialized equipment is the industry gold standard for application of rapid setting, plural component polyureas that require high temperatures and pressures for application.

As any good applicator will tell you, the number one cause of industrial coating failure is poor or out-of-spec surface preparation. This is also true of polyurea. Careful surface profiling and cleaning is essential to creating a bond between polyurea and the substrate. Titan owns and maintains mobile abrasive blasting and concrete grinding equipment and expertise to ensure that the substrate surface is properly profiled, cleaned and ready for coating.